Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

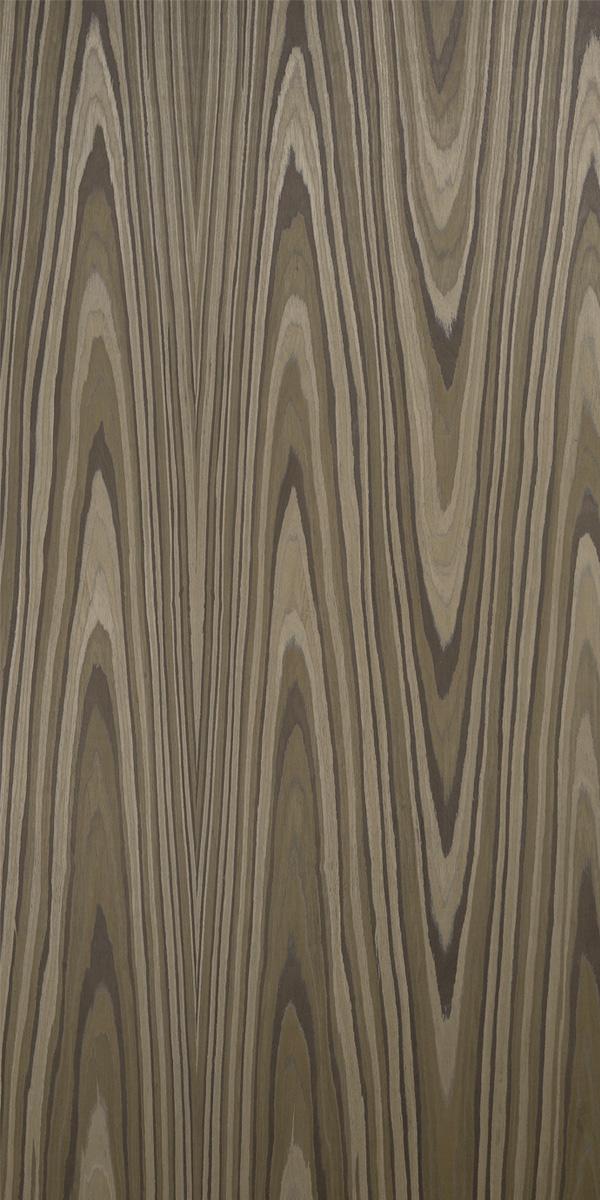

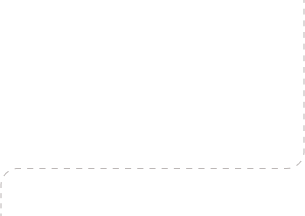

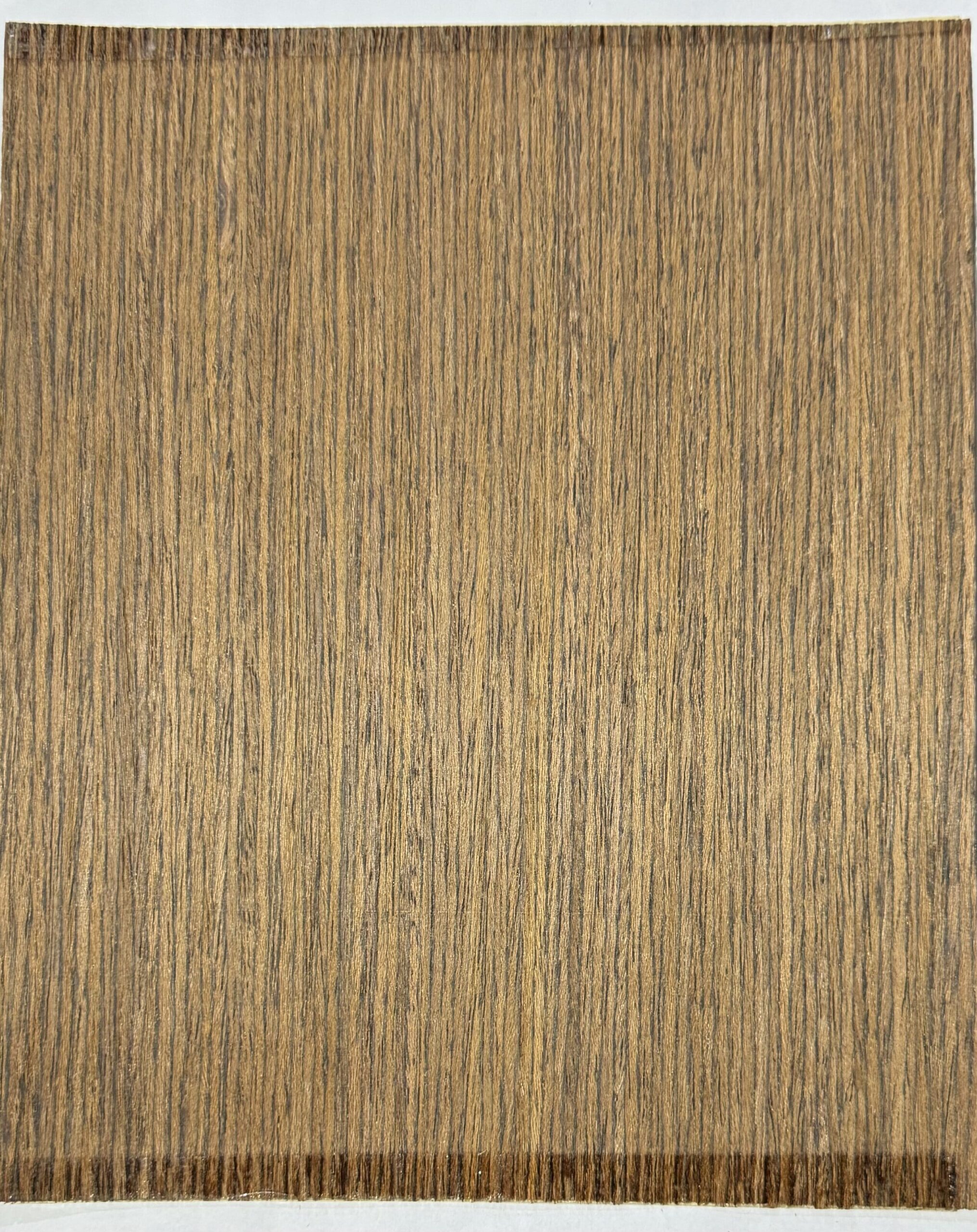

Engineered veneer (EV) – also known as reconstituted veneer (recon) or recomposed veneer (RV) – is a remanufactured product.

Like natural veneer, engineered veneer is real-wood and born from a natural core. The difference is that the veneer is engineered though templates and pre-developed dye moulds. This means that typically engineered veneers will be more consistent in terms of appearance and color – and will generally be free of surface knots and other natural characteristics found in each species, while still maintaining the natural wood grain from the core species used.Engineered veneer sheets are derived from renewable tree types.

Artificial veneer sheets are intricately designed to mimic the distinctive grain patterns found in natural veneer. Employing a patented process, these sheets replicate similar designs on a larger scale. Ideal for decorative purposes, options like designer veneer and metallic veneer offer a perfect choice for enhancing surfaces, including furniture, walls, and flooring.

For centuries, solid wood has been the cornerstone of exquisite furniture and captivating interiors. But what if there was a way to achieve that same timeless elegance with a material that boasts enhanced functionality with a lower cost. Enter engineered veneer, a revolutionary product rapidly transforming the design landscape.

Engineered veneer goes beyond the limitations of traditional wood. It’s crafted by reconstituting genuine wood elements – thin slices or strands – and bonding them to a stable core substrate. This innovative process unlocks a multitude of benefits: