Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

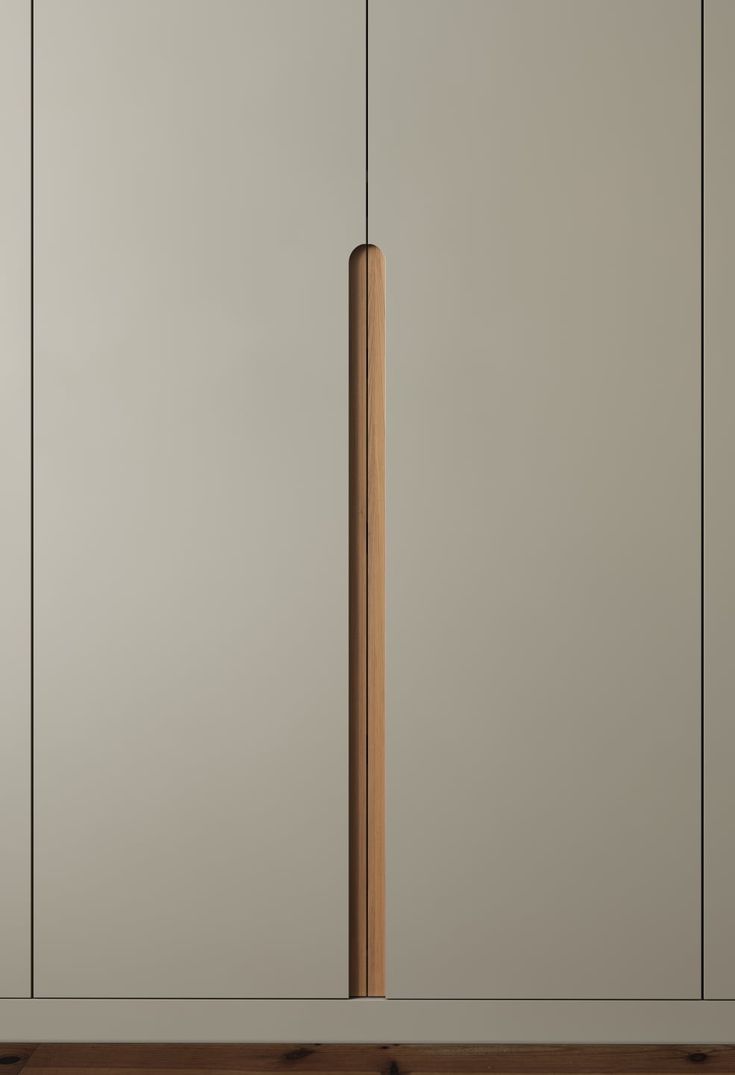

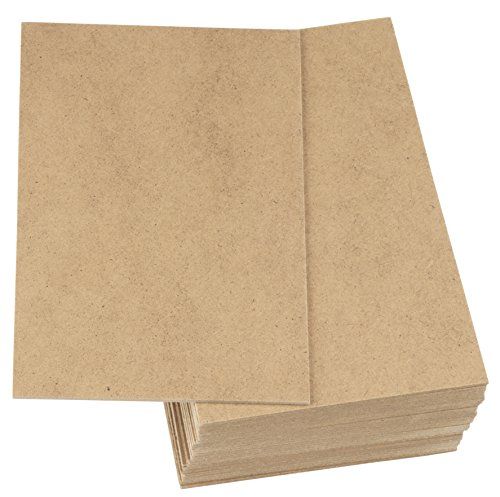

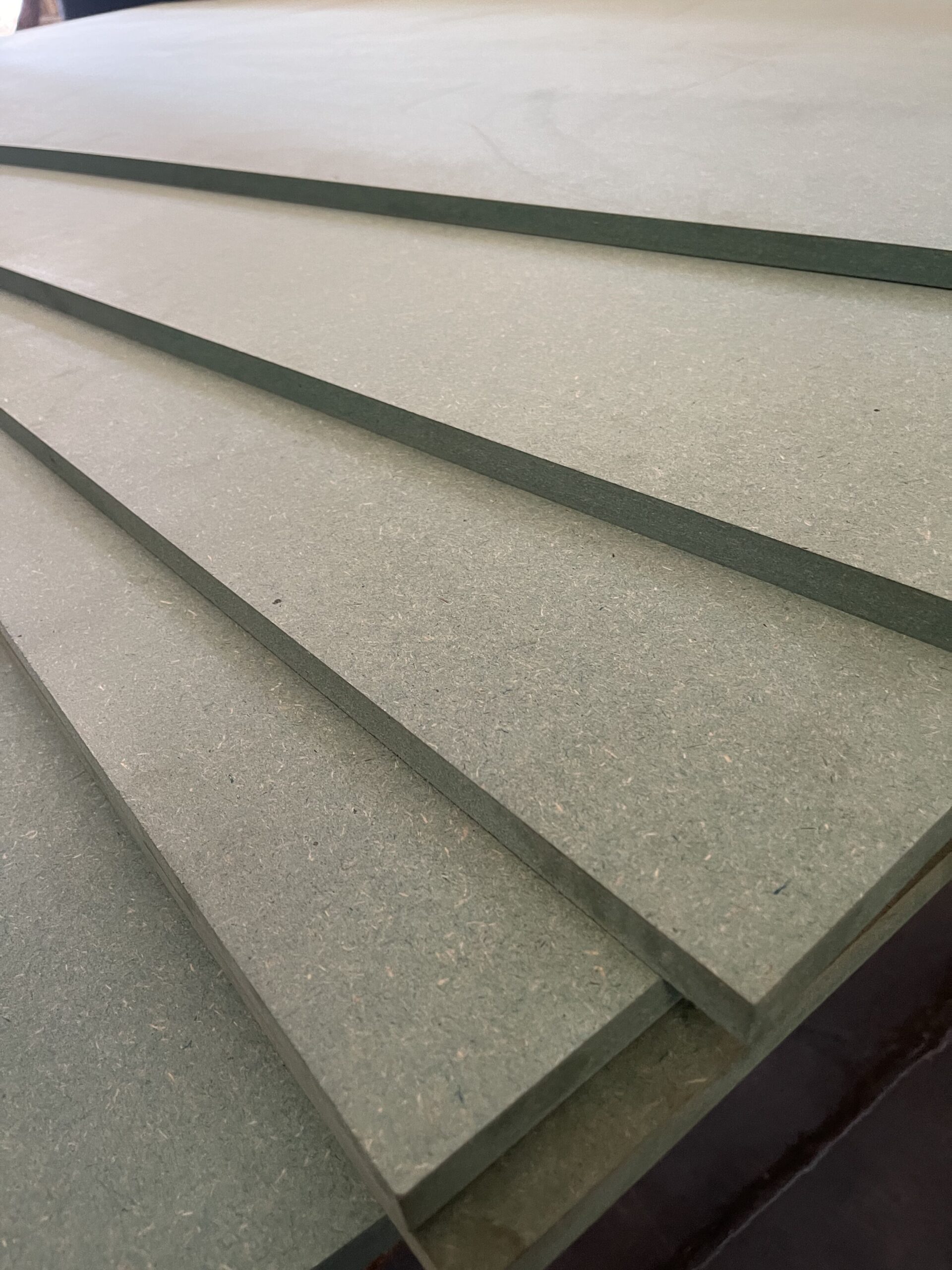

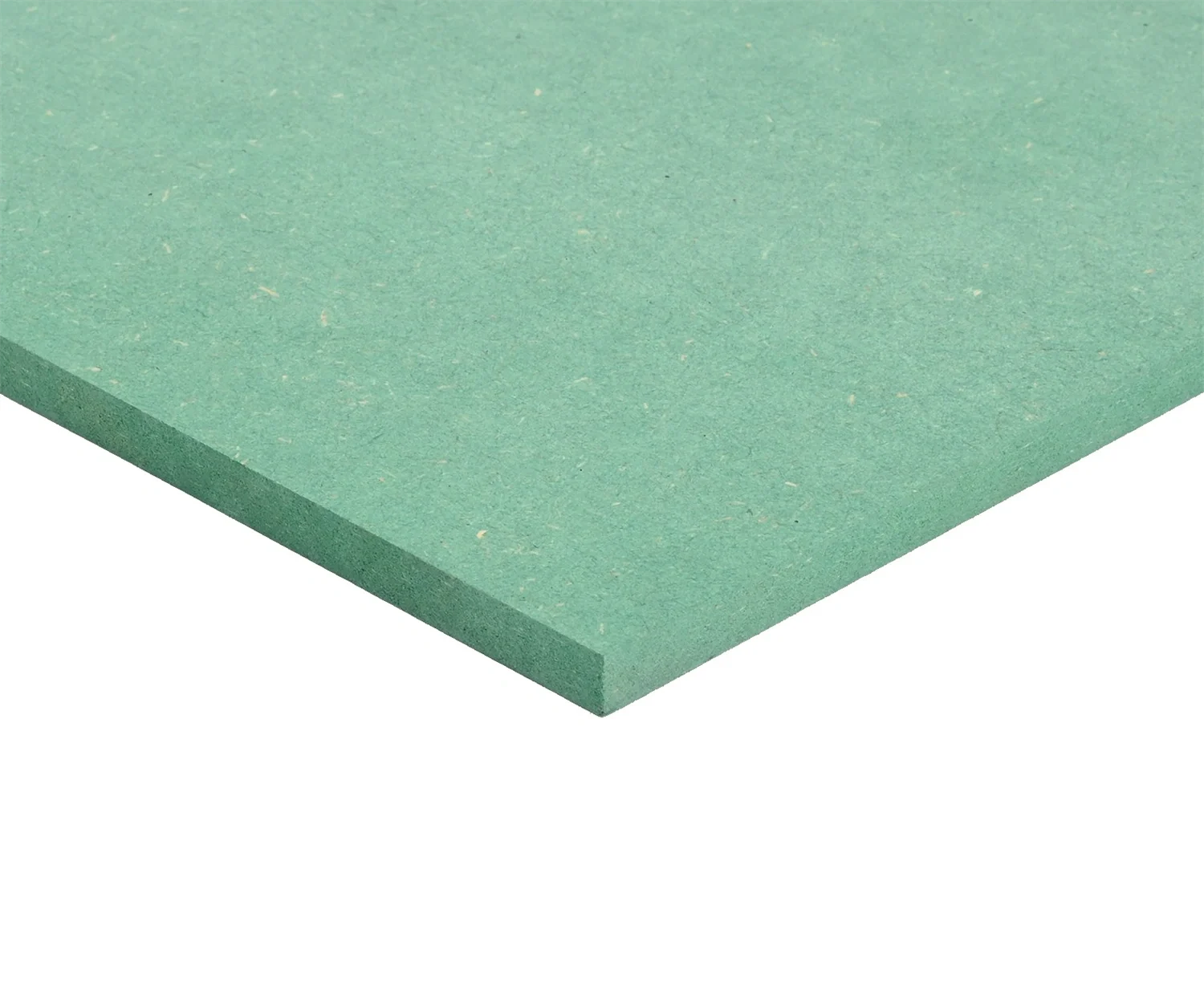

Fiberboards are engineered wood products made from compressed wood fibers and adhesive, offering a wide range of applications in construction, furniture making, and interior design.

Fiberboards offer a wide variety of sizes to meet the requirements of any project. The sizes offered are:

Size of FIberboards :

Thicknesses:

Thicknesses can vary from 1.5mm to 30mm

Emissions:

E0.5, E1, E2

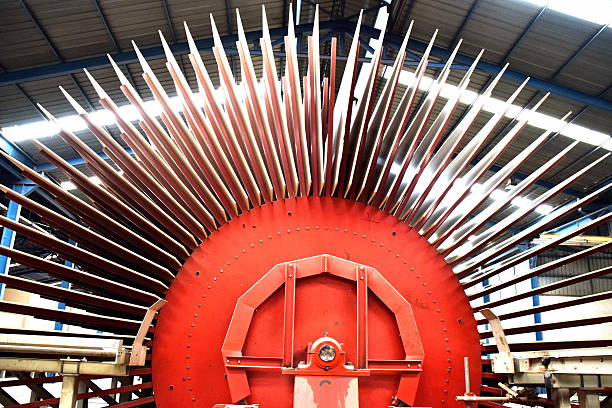

Wood Chipping

Wood ChippingFresh or recycled wood material is cut and sorted into small pieces of similar size.

Chips Cleaning

Chips CleaningChips are washed to remove things such as dirt and sand. Metal scraps such as nails can be removed with a magnet placed over a conveyor belt on which the chips move forward.

Steaming

SteamingIn the case of, for example, MDF (medium density fiberboard) and not particle board, chips are then steamed to soften them for defibration.

Chemicals Application

Chemicals ApplicationSmall amount of paraffin wax is added to the steamed chips and they are transformed into fluffy fibers in a defibrator and soon afterwards sprayed with adhesives such as urea-formaldehyde (UF) or Phenol formaldehyde resin (PF). Wax prevents fibers from clumping together during storage. Chips in the case of particle board are also sprayed with a suitable adhesive before the next steps.

Pressing

PressingFibers or chips are arranged into a uniform “mat” on a conveyor belt. This mat is pre-compressed and then hot-pressed. Hot-pressing activates the adhesive and glues the fibers or chips together.

Finishing

FinishingBoard is then cooled, trimmed, sanded and maybe veneered or laminated.