Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

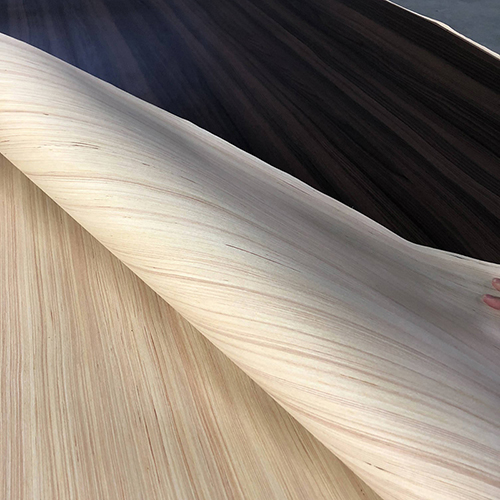

In the realm of interior design and architecture, laminates play a crucial role in enhancing the aesthetic appeal and functionality of wood panels. Among the various options available, Melamine Paper Laminates and High-Pressure Laminate (HPL) stand out as popular choices due to their versatility, durability, and affordability.

Melamine Paper Laminates consist of a single decorative paper layer impregnated with melamine resin, which is then bonded to a very smooth flat surface such as particleboard or MDF (Medium-Density Fiberboard). Melamine paper laminates are typically applied using heat and pressure, resulting in a thinner and less robust surface. While melamine paper laminates offer a wide range of designs and are cost-effective, they may not possess the same level of durability and resistance as HPL.

High-Pressure Laminate, commonly known as HPL, is a composite material made of multiple layers of kraft paper impregnated with phenolic resin. These layers are bonded together under high heat and pressure, resulting in a sturdy and resilient sheet. The top layer is adorned with a decorative melamine paper, designed to mimic various materials such as wood, stone, or metal. HPL is renowned for its durability, resistance to scratches and impacts, and ease of maintenance, making it a popular choice for both residential and commercial applications.

Melamine Fiberboards

Size: 1220*2440, 2200*2800

Thicknesses: from 1.9mm to 24mm

Paper weight: 60 to 80 grams

HPL

Size: 1220*2440

Thicknesses: 0.4, 0.5mm