Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

Our Contact

Edit Content

Wood Product Supply

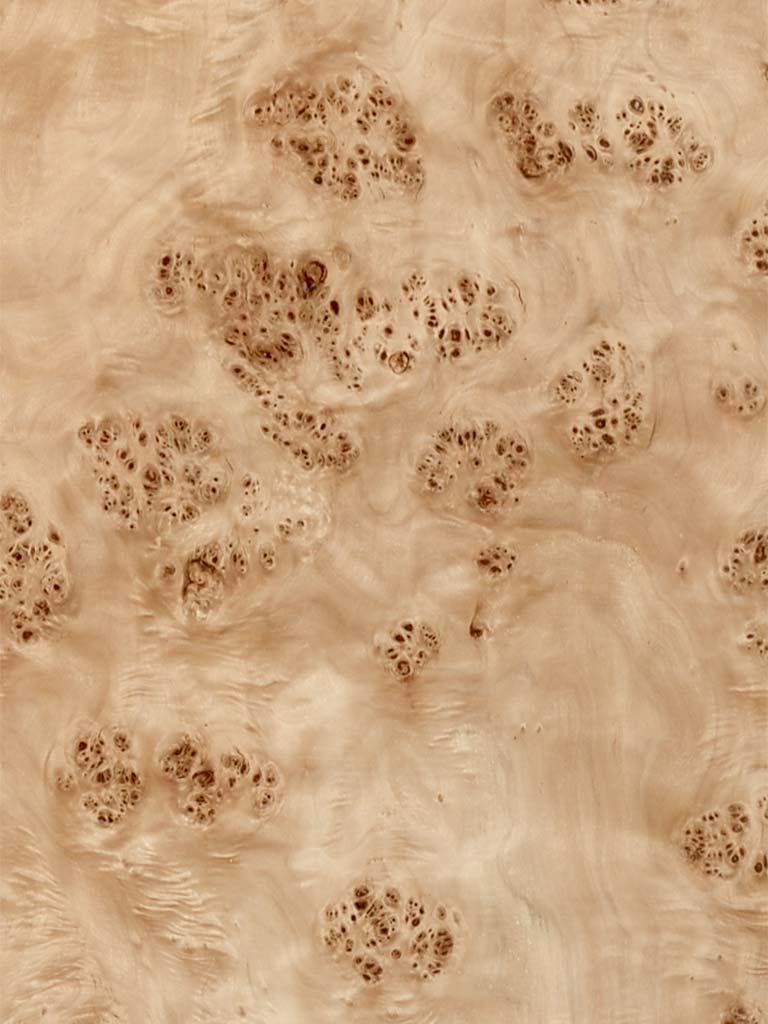

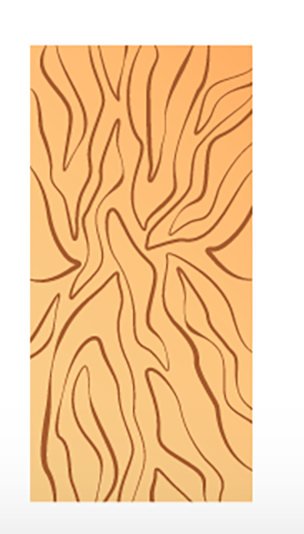

Wood Veneer Is the whispered echo of a grand forest, captured in a paper-thin slice. Wood veneer refers to thin slices of real wood logs, typically less than 3mm thick. Veneer is obtained either by “peeling” the trunk of a tree or by slicing large rectangular blocks of wood known as flitches.

The appearance of the grain and figure in wood comes from slicing through the growth rings of a tree and depends upon the angle at which the wood is sliced. These slices are adhered to a stable core material like plywood, MDF, or particleboard to create panels that can be used in various applications. This creates a composite panel offering the aesthetic appeal of solid wood with improved functionality. Veneers transform ordinary surfaces into shimmering panels of grain and texture.

Full-length offerings:

The creation of wood veneer involves precision and craftsmanship. Here’s a simplified look at the process:

Log Selection

Log SelectionHigh-quality logs are chosen, often from the top section of the tree for the best grain patterns.

Soaking and Preparation

Soaking and PreparationThe logs undergo a lengthy soaking in hot water vats, softening the wood for easier slicing.

Slicing Techniques

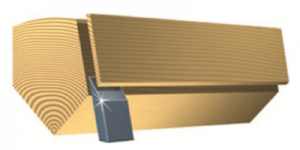

Slicing Techniques

Drying and Finishing

Drying and FinishingThe sliced veneer is carefully dried and may be dyed or stained to achieve desired colors.

Clipping and Packing

Clipping and PackingOnce the veneer is dried, it goes to the clipping machine to sharp cut the edges and unify them. Then, the sheets are packed in bundles.

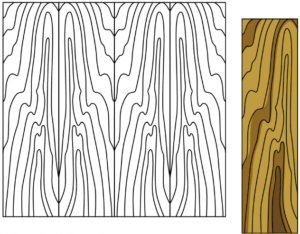

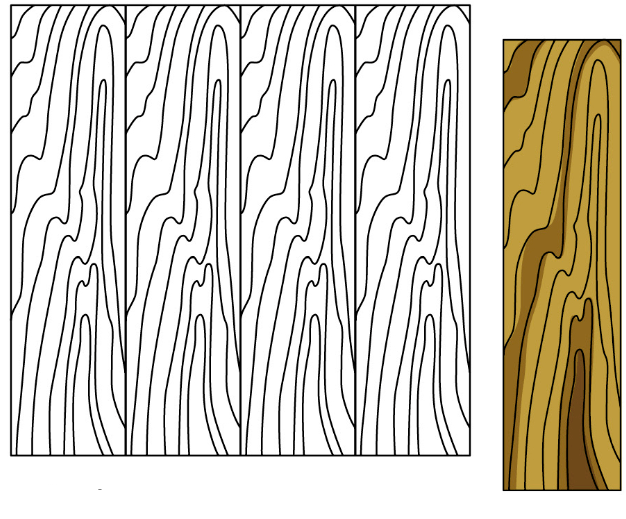

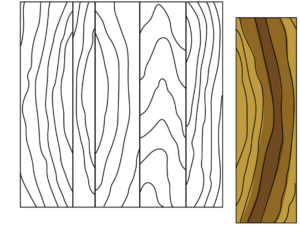

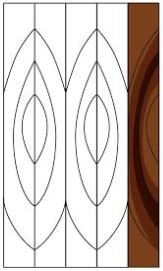

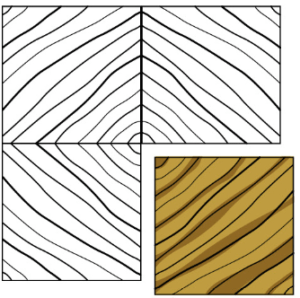

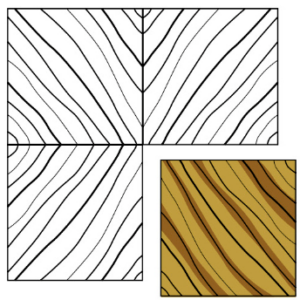

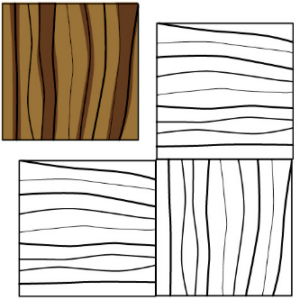

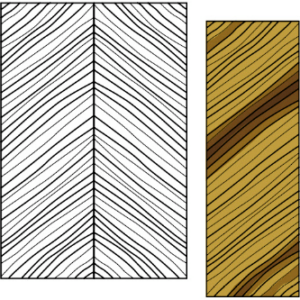

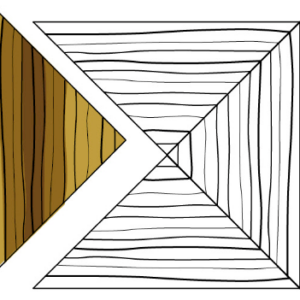

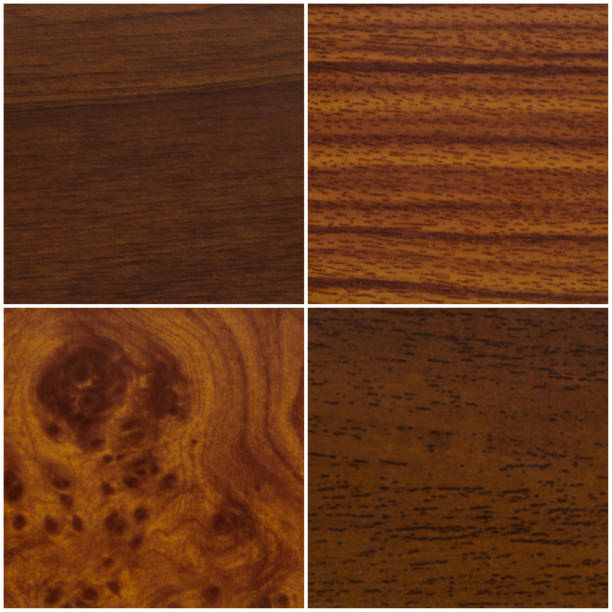

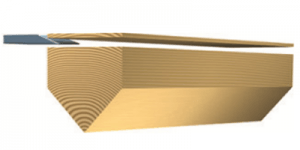

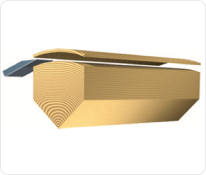

The grains and figures in wood veneer come from slicing through the growth rings of a tree and depend upon the angle at which the wood is sliced. There are five main techniques of veneer slicing, as shown below, resulting in different grain appearance

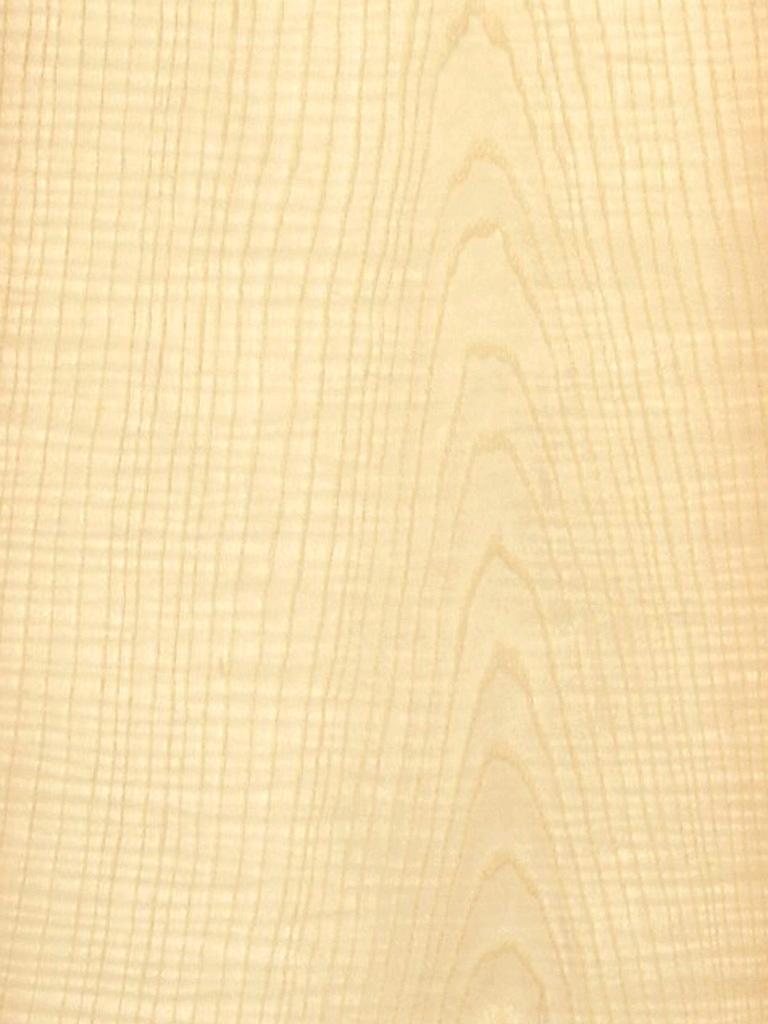

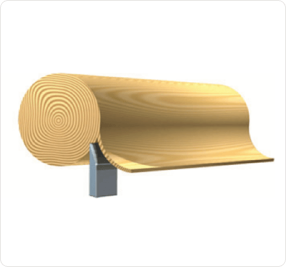

A whole log is mounted in the center of the lathe and turned against a sharp blade, much like unwinding a roll of paper. It is the most economical method of cutting. Rotary cut veneer can be wide enough to produce a full-sheet, or single piece faces.

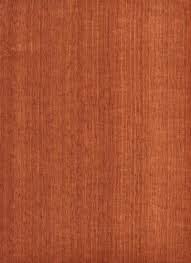

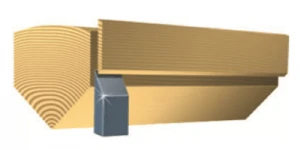

A quarter log is mounted on the flitch table so that the growth rings are perpendicular to the cutting blade, producing a series of stripes. These stripes can be straight in some woods and varies in others.

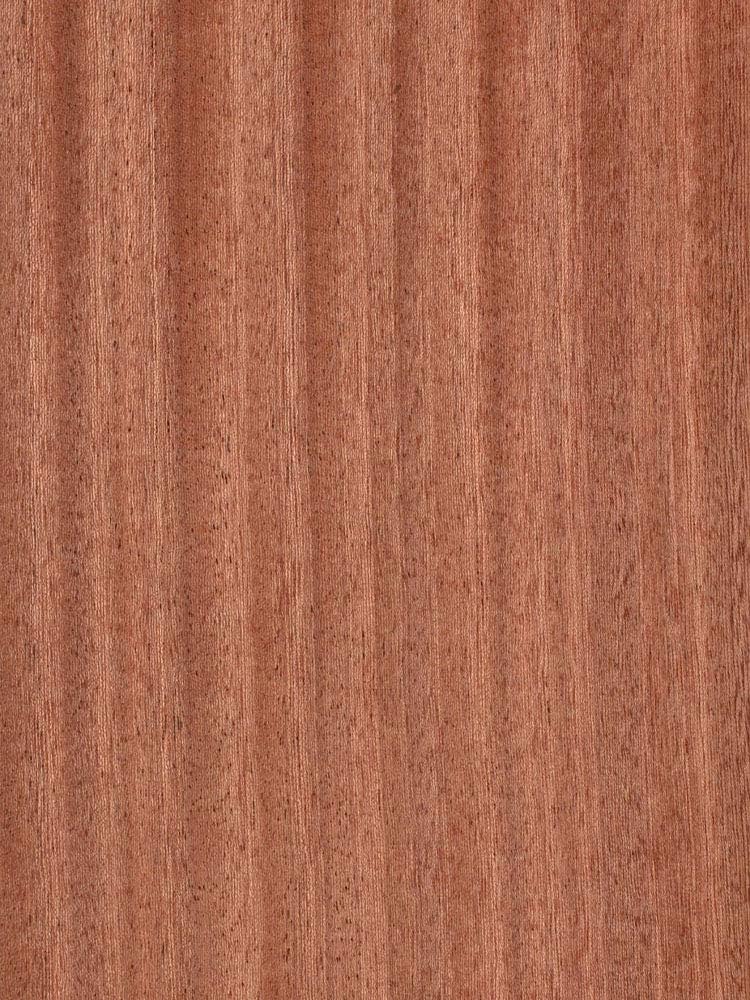

A half log is mounted with the heart side flat against the flitch table of the slicer. The cut is then made with the blade parallel to the length of the log producing the appearance of a “cathedral effect”.

A half, third or quarter of a log is attached to a plate on a lathe and turned. Half-round slicing is used to accentuate the different grain in certain woods. However, it can also be used to achieve a flat/ plain sliced veneer appearance.

A quarter of the log is fixed to a plate on a turning stay log. As the flitch is rotated, the blade and angle can be varied so that the wood is cut exactly to produce the very straight rift grain. Rift slicing uses a “stay log lathe,” which cuts with a rotary action. Rift slicing also achieves a straight grain pattern, but avoids the appearance of “flake” that occurs in some species when quarter sliced. Most often, this method is used with oak and it is generally the straightest and free from cathedrals and variations in grain.